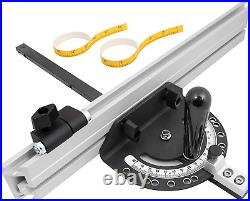

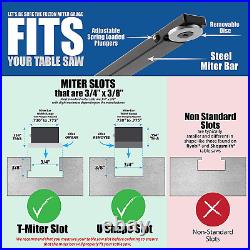

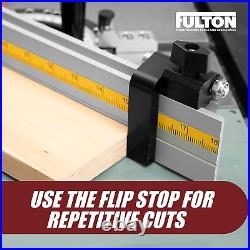

The Fulton Miter Gauge is a high quality, well thought out and economical solution for your table saw cross cutting needs. The Aluminum Miter fence is equally well thought out with its 45 degree ends for unsurpassed workpiece support and its ability to mounted to most any miter gauge. Also included is a handy aluminum flip stop for repetitive angled cuts on your table saw. Together these three items are the perfect compliment to each other for your table saw cutting needs. 200 thick, adjustable, solid aluminum head is machined with 13 positive stop holes. 1 hole is at 90 degrees while the 6 holes on both sides are at 22.5, 30, 45, 60, 67.5 and 90 degrees. The head is mounted to a solid steel miter bar that measure 18 in length and is. Standard miter slots are 3/4″ x 3/8″ with a 1/8″ “T slot (slight variances from brand to brand) running the length on the bottom of the slot. The steel miter bar is equipped with a metal, removable retaining disc that measures 7/8″ in diameter and is just shy of 1/8″ to fit into to the “T” slot to prevent accidental lifting when feeding your stock through. Made from a single piece of extruded aluminum, this precision miter gauge fence is not only durable, its accurate and saves setup time. The fence is designed to be used with most any miter gauge with its off-set mounting track on the back of the fence. The off-set track allows you to flip the fence for lower profile miter gauge mounts and flip back for standard height miter gauges. The fence can be mounted to older miter gauges by adding a wooden block mount with wooden screws if necessary. Both ends of the fence are cut at exactly 45 degrees. This allows you to position the fence extra close to the saw blade (with the power turned off) so you have even more control over the workpiece you are cutting. The fence comes with a flip stop that makes repetitive cuts a breeze. When not in use the flip stop can be flipped up and out of the way. Also include are two sticky back measuring tapes. 1 tape is left to right reading and the other is right to left reading. Fulton Precision Miter Gauge with Aluminum Miter Fence and Flip Stop. We’ve all done the research or at the very least heard about miter gauges with fence systems that are very accurate, easy to adjust and make cross cutting angles on your table saw super easy. While that all sounds great, all those great features usually costs a lot. That is until now! The Fulton Precision Miter Gauge with Aluminum Miter Fence and Flip Stop comes packed with all those great features and more. The best part is that it is reasonably priced so that most any woodworker can afford it! Be Precise with Ease. If you have ever used a factory supplied miter gauge, then you know how limiting it can be. The Fulton Miter Gauge with Aluminum Fence and Stop makes the angle cutting process a breeze. Once the gauge is set and the fence is properly adjusted, cross cutting angles on your table saw just became a whole lot easier than just using a miter gauge by itself. When this aluminum fence is used with the Fulton Miter Gauge, you’ll be able to repetitively cut angle stock all day long with precise results! When designing the fence for this system we kept having the same issue happen over and over again. The standard 90 degree end on most miter gauge fences made the fence to saw blade gap too large and the wood kept binding in that gap. Our solution was to simply cut the fence ends at a 45 degree angle so that the fence can get as close as possible to the blade with minimal stock over hang. This helps prevent binding and produces a much cleaner cut. Convenient Aluminum Flip Stop. Included with the fence and miter gauge is a convenient flip stop for making repetitive cuts. Simply slide the flip stop to the exact position you need it to be, lock it in place and you’re ready to go! When the stop is not needed you can either remove from the fence or simply lift the stop upwards and out of the way until it is needed. Accurate and Easy to Adjust. The Fulton Miter Gauge is loaded with great features. One of the more prominent features are the positive stops that are set to the most common angles used by woodworkers. Simply loosen the handle by rotating it counter clockwise, pull the spring loaded pin lock up and and adjust the miter gauge to the desired angle. Once you find your positive stop angle, release the lock pin so it locks the angle in place and re-secure the handle by rotating int clockwise until it is snug. If you want to use an angle that is not one of the positive stops, the pin lock can be pulled upward and rotated so that it won’t engage any of the positive stop holes. This allows you to adjust the miter gauge to any angle you need. Left Side, Right Side or Even Upside Down.. For the most part, we tend to cut on one side of our table saw the majority of the time. It usually depends on the saw or just simply preference. This is why we included two different sticky back (PSA pressure sensitive adhesive) tapes so you can choose which direction you need. We also know that some of use like to do things a little differently. If you are looking down at your miter fence from above then it may make sense for some of us to place the tape on to the aluminum fence upside down in relation to the miter gauge. This allows for you to be able to clearly read the measurements on the tape. Standard Size Miter Bar 3/4″ x 3/8″. The steel miter bar is mounted to the miter gauge and is the industry standard of 3/4″ x 3/8″. This means it will fit into most table slot miter slots. The miter bar also features spring loaded plungers that can be adjusted (with a hex key wrench) for just the right fit so you have a smooth push through every time.

No comments